Emergency Disaster Relief Metal Buildings

Our Emergency Disaster Relief Steel Buildings are perfect for rapid deployment. They are engineered to withstand extreme weather conditions and seismic activity, providing superior protection against snow accumulation, hurricane force winds, fire hazards, and seismic ground movement.

They serve as an invaluable asset in disaster relief efforts due to their speed of deployment, durability and strength, cost-effectiveness, flexibility, and sustainability. They play a vital role in providing safe, secure, and efficient shelters while supporting communities in their journey toward recovery and resilience.

Disaster Relief Steel Building Uses:

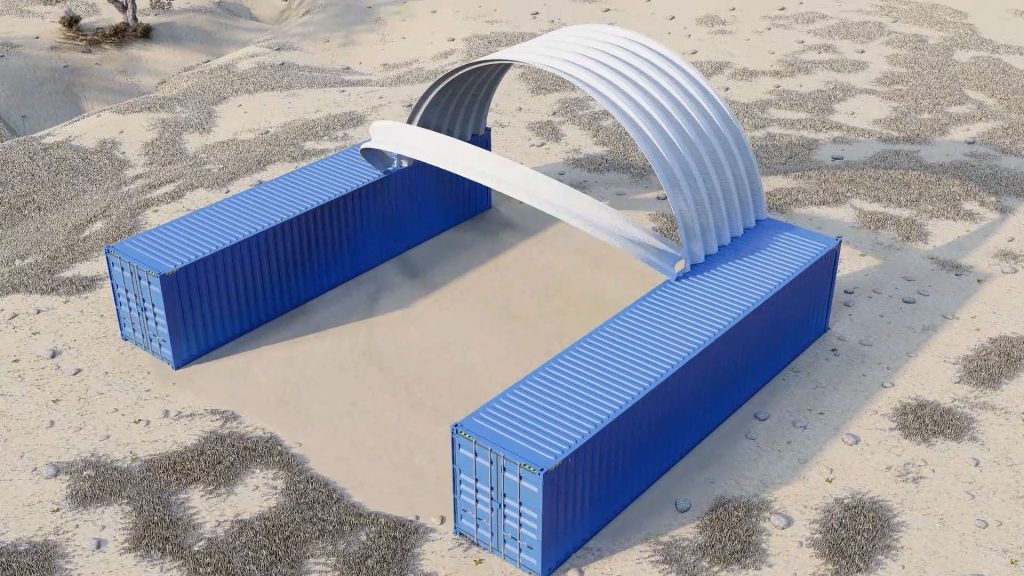

Our Disaster Relief Steel Buildings can be used in a wide variety of ways. They can be placed between two shipping containers to maximize otherwise wasted space. If you are looking for something more permanent, you can attach our arch buildings to any size concrete wall giving the structure additional height while displacing water that would otherwise enter the building in a conventional build. Ideal for compact ocean shipment and rapid delivery in little as 2 weeks.

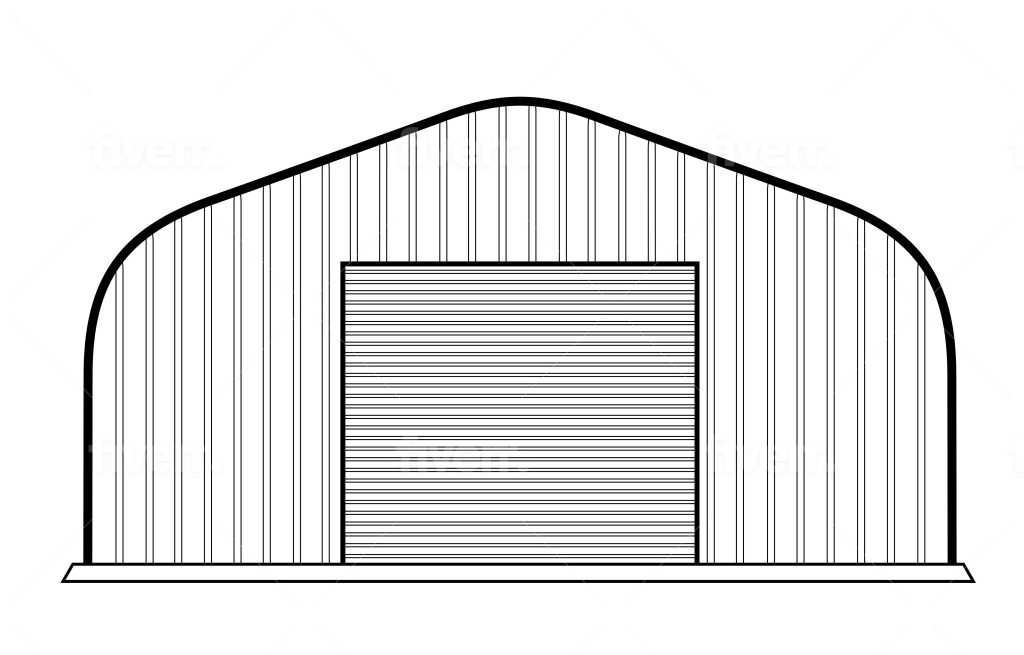

(Deployment Headquarters)

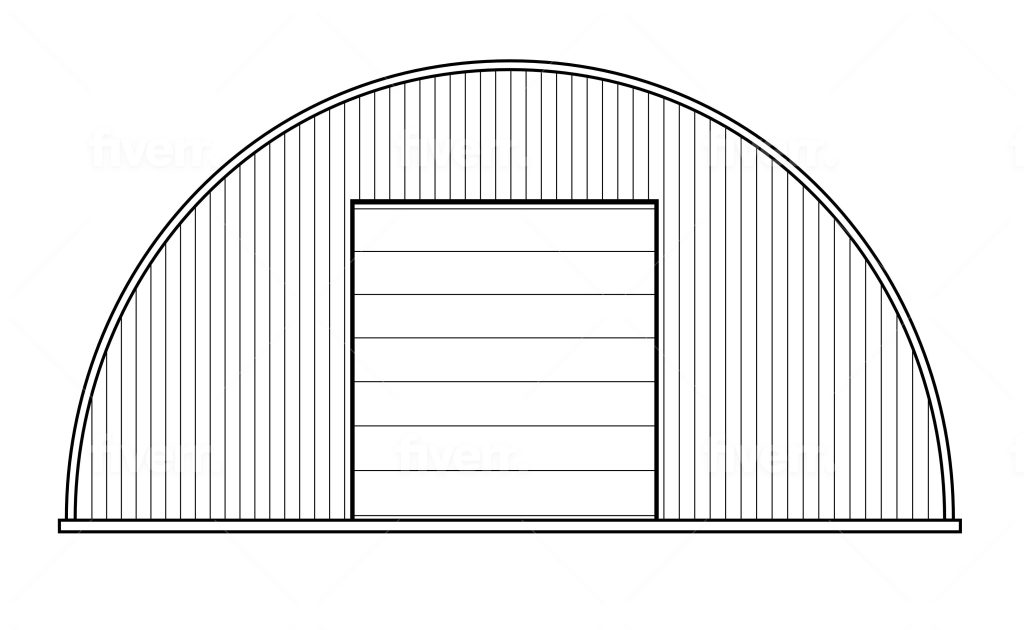

(Maintenance Sheds)

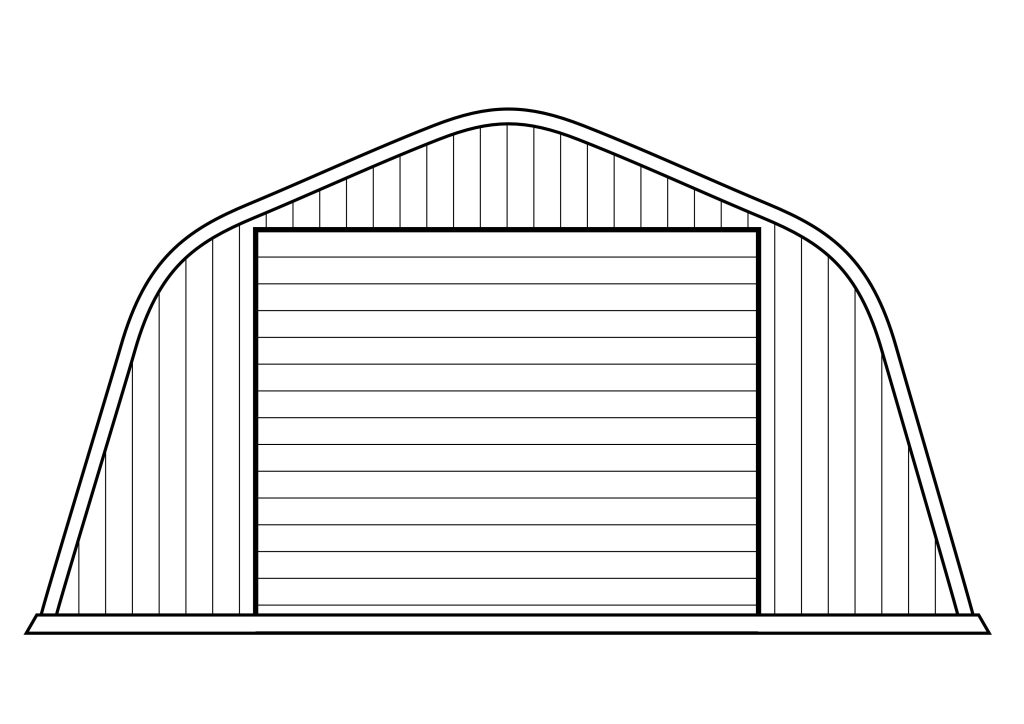

(Distribution Center)

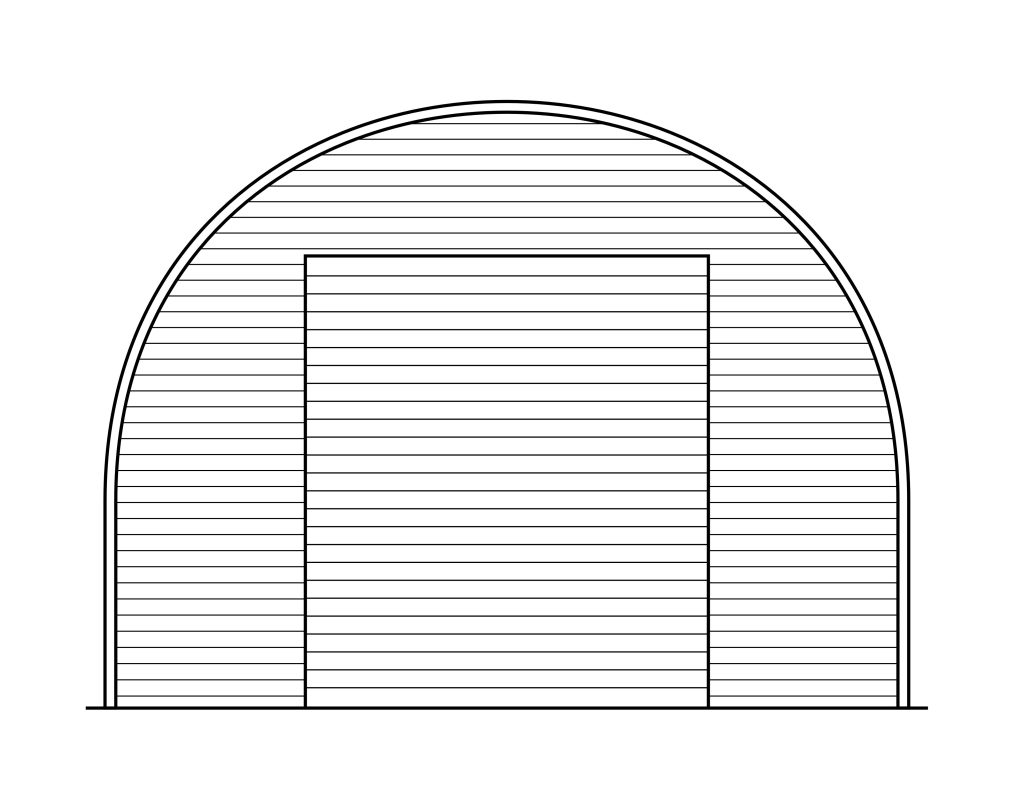

(Enclosed Secure Storage)

Benefits of Quonset Emergency Relief Shelters

Our Quonset emergency relief steel shelters are ideal for compact low-cost ocean freight with added benefits:

- Rapid Delivery (2 Weeks)

- Rapid Deployment (2-3 Days)

- Clear-Span Column Free Interior (Maximum Square Foot Storage)

- Heavy Duty Designed for Hurricane Winds and high seismic zones

- Simple Fast DIY assembly

Small to Large Scale Operational Centers using Container Roof Kits

A Shipping Container Roof for a rapid response steel building offers unparalleled speed of construction, making it ideal for urgent building projects. They go up fast using pre-fabricated steel, significantly reducing erection time compared to conventional style buildings. The modular design ensures easy transportation and quick on-site installation, enabling immediate deployment in emergency situations.

We use heavy duty gauge steel and every building is engineered for the do-it-yourselfer. With simple ladders and rope, a team of a few people, the completion of your shipping container roof is only days away!

Operational Headquarters for Ground Deployment Services

Curvco’s Arch Steel Buildings provide exceptional benefits in the Caribbean islands to use as facility and utility buildings for ground operation deployment. Our robust steel construction ensures strength & durability against tropical weather conditions, including strong hurricane force winds and heavy rainfall common in the region.

With easy-to-erect foundation and erection manuals, these buildings are ideal for rapid deployment as storage facilities, maintenance centers, or operational headquarters during emergencies for support.

Emergency Relief Steel Building Models

Our Emergency Relief Steel Buildings can ordered using any model we offer! Depending on your requirements and design, we can ship a building that meets or exceeds the load ratings and ensures safety with our heavy duty gauge steel manufactured in the USA!

DIY Prefab Building Construction

Our Prefab DIY Steel Buildings use a one size nut and bolt construction and are made for the do-it-yourselfer which compared to conventional construction can easily save you thousands! These prefab buildings are designed to be erected in rapid time using basic tools. Our Disaster Relief Buildings are compact and can be shipped inside a cargo container to virtually anywhere on earth.

Rapid Response Roof Kit Construction

With our Container Roof Kit Construction process you will either bolt or weld the provided attachment plates to the inner or outer edge of the shipping container. Customers may choose to either build their own end walls or purchase one from the factory for an inclusive install.

Prefab Steel Building Standard Construction

Our Prefab Steel Building standard construction process starts with assembling the arch panels on the ground to create full arches by bolting them together. Next, Raise the arches into place. Secure and bolt the arches together until the structure is complete. Add the end walls or build your own for a unique look.

Get a price on a Disaster Relief Hurricane Steel Building!

Combat Extreme Weather with Disaster Relief Buildings

Curvcos Disaster relief steel buildings are highly resistant to extreme weather. Our heavy duty American steel is dipped in a galvalume coating which further protects and enhances its resistance to any elements. Although nothing is tornado proof, our steel structures in the past have combated tornados with great success. These steel building kits are more fire resistant than conventional buildings containing wood or other building materials. Every Steel Building manufactures is pre-engineered to withstand hurricane rated winds and even earth quakes.